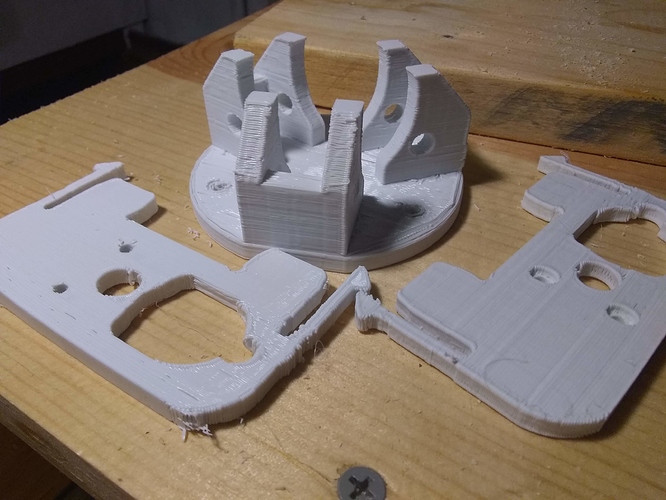

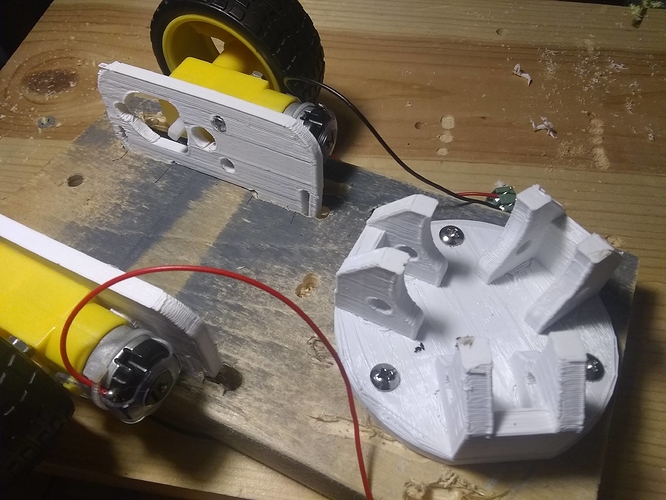

So I tried 3D printing the parts. They work without modification but the clip parts are weak with my poor printer tuning and non-ideal printing orientation. Coincidentally, they work fine with TT motors.

The primary part I was interested in printing, the golf ball caster, printed as one piece acceptably.

You could print these on a better printer with a better tuning and get much better results.

My attempt at making slots was really horrific but works fine as a rough prototype.

I would much prefer the slotted 2D parts as machined parts rather than printed. I don’t think it matters much for the golf ball caster. The main advantage I see from printing the caster is that less assembly is required.