I do have something in mind. I am planning to finish fully documenting my design after I take in to account the feedback I got at the meeting. I’ll start posting what I have once I’ve made some progress on that.

Unfortunately I can’t put any time in this week until I’ve finished all my assignments for this semester.

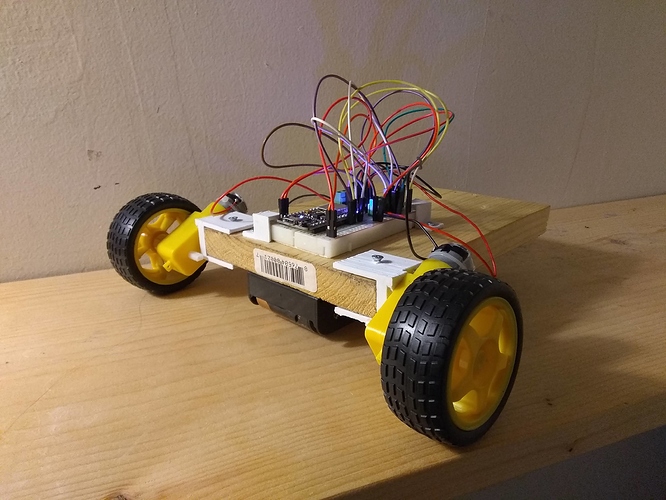

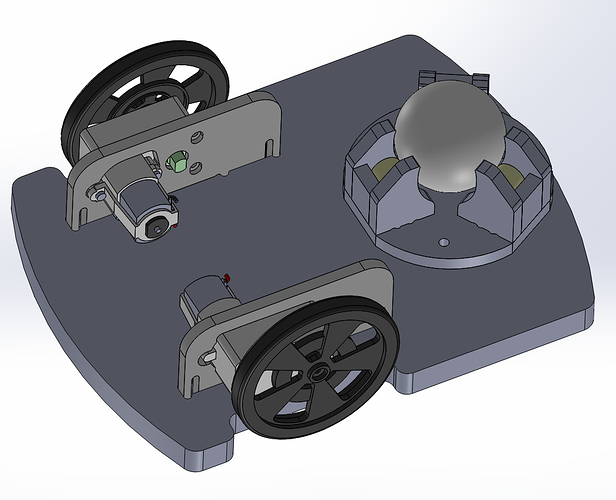

I would like to try a prototype with continuous rotation servos, but for the moment I’m going to focus on TT Motors because they are currently working in the design.

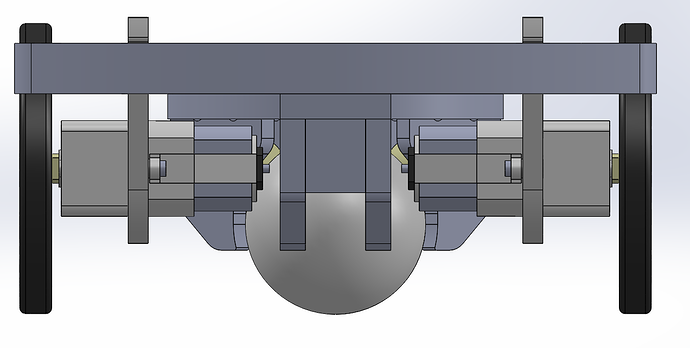

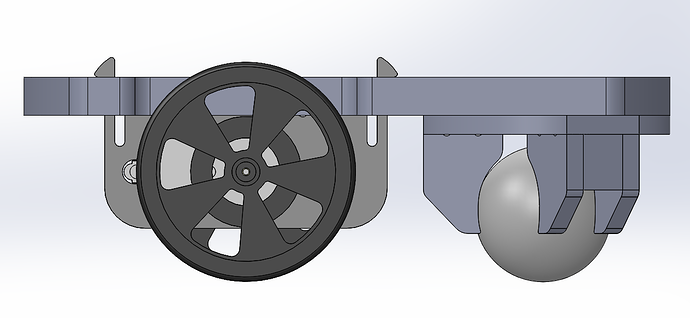

I also plan on trying a ball caster to see its effectiveness on my carpet.

Here is a list of my current planned changes:

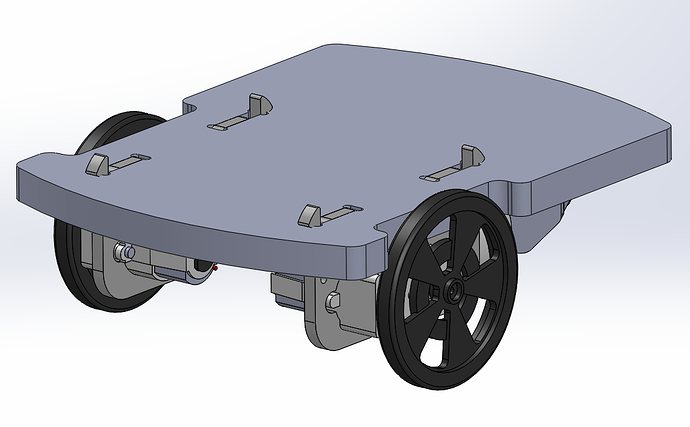

- Define a standard size. (Thinking about 6in width 8in height but subject to change on feedback)

- Make base design possible to laser cut and put files on discourse.

- Tweak parts to account for unknown thickness of base

- Round corners of base. Shift motors back to account for this.

- Define slot in base for motors and wheels so the outer edge of the wheels is just inside the planned width.

- Create better breadboard bracket that is a one piece printed part. (I have an existing working design from another robot I just need to tweak.)

- Use AA battery box rather than C battery box.

- Change pin used for one motor direction so it doesn’t spin when code is uploading.

- Change holes to use American sizes, not metric.

It will be designed in mind such that if someone takes just a rectangle of wood, only drills holes, and does not put slots in it, they could still create a functional robot (perhaps minus encoders).

Because Fusion 360 is unusual for CAD in that it’s cloud based saving, I’ll post a viewable link to my design rather than the files themselves.

For full documentation the first step will be finishing the CAD assembly so every part is included. Second step will be documenting the electronics wiring with a visual breadboard layout tool. Third step will be creating a Google Docs document with assembly instructions with pictures.

Edit:

It will also be designed in mind such that you will not have to use wood, but could use any flat material.